| |

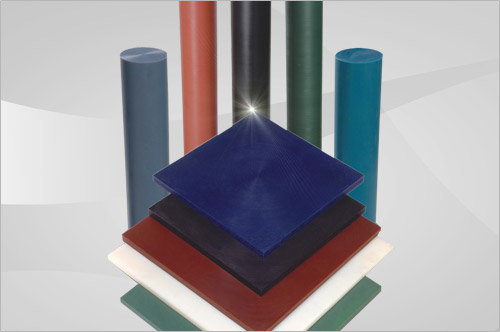

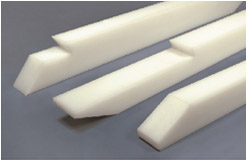

| Kaylon is partially csystalline polyamide and have to managed to gain a key position in engineering plastic through the combination of high strength the toughness even strength and high toughness even a low temperature. Polyamide has become a multi purpose plastic. It has the following outstanding properties. |

| |

|

Good toughness

|

|

|

High dynamic load bearing capacity

|

|

|

High strength and stiffness |

|

|

Almost no tension crack formation |

|

|

Good chemical resistance |

|

|

Good Gas barrier properties |

|

|

Higher temperature operating capacity |

|

|

Good wear and abrasion resistance |

|

|

Low internal stresses and good dimensional stability |

|

|

Excellent abrasion resistance |

|

|

Excellent Flexural strength |

|

|

Very good operation without lubrication |

|

|

|

|

| |

|

| TECHNICAL DATA |

| Property |

|

Test method |

|

Unit |

|

Kaylon |

|

Kaylon oilon |

|

Kaylon moly |

|

Kaylon HS |

| Density |

ISO 1183:1987 |

g/cm3 |

1.14 |

1.15 |

1.14 |

1.14 |

| Water Absorption |

ISO 62:1999 (modified) |

% |

0.3 |

- |

0.2 |

- |

| Tensile Strength |

ISO 527-1/2:1999 |

Mpa |

80 |

75 |

85 |

80 |

| E Modules |

ISO 527-1/2:1993 |

Mpa |

4000 |

4000 |

4100 |

4000 |

| Compressive strength |

ISO 604-2002 |

Mpa |

95 |

95 |

105 |

95 |

| Elongation at Break |

ISO 527-1/2:1993 |

% |

>20 |

>30 |

>20 |

>20 |

| Flexural strength |

ISO 178:2001 |

Mpa |

105 |

100 |

115 |

105 |

| Izod Impact (notched) |

ISO 180-2000 |

Kj/m2 |

5.6 |

6 |

4.5 |

5.4 |

| Hardness ( shore D) |

ISO 868:2003 |

- |

84 |

83 |

85 |

84 |

Co-efficient of friction (Dynamic)

|

- |

- |

0.39 |

0.15 |

0.25 |

0.15 |

| Wear Rate |

- |

Mg/km |

0.44 |

0.11 |

- |

- |

| Max. intermittent services Temp. |

- |

°C |

170 |

170 |

170 |

180 |

| Max. continuous |

5000 hrs. |

°C |

100 |

110 |

105 |

115 |

| services Temp. |

IEC 60243-1: 1988-01 |

Kv/mm |

25 |

25 |

25 |

25 |

|

|

| |

| |

| |

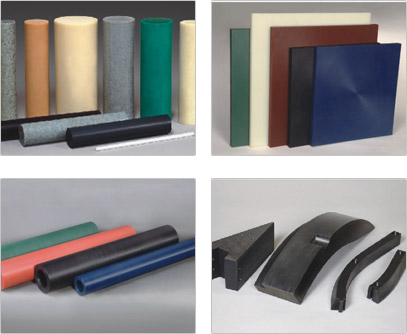

| Application: |

| Kaylon components can be used in many diverse application in industries including construction, oil and Gas, pharmaceuticals, food Processing, Railway, Mining, Water Treatment and automotives. Some of the products Are: |

|

Gear, sprockets, wear pads for telescopic booms |

|

|

House pulleys |

|

|

Chute liners |

|

|

Bearing, Bushes

|

|

|

Guide plates, chain guides

|

|

|

Wiper shields

|

|

|

Shaft support |

|

|

Out rigger pad |

|

|

Wear strips |

|

|

|

|

|

| |

| |

| |

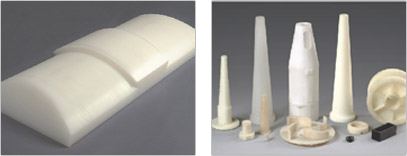

| Kaylon’s properties are useful for mining and construction industries |

|

Exceptional resistance to wear and abrasion. |

|

|

Light weight, typically 1/6 th of the weight of steel.

|

|

|

Self lubricating resulting in low maintenance cost.

|

|

|

Low co-efficient of friction |

|

|

Life is 25 times the life of similar components in phosphor bronze |

|

|

Corrosion and chemical resistance. |

|

|

|

|

|

| |

| |

| |

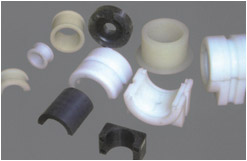

| Kaylon’s Alloy for different application: |

| kaylon oilon |

| FEATURES: |

|

Low wear and abrasions resistance

|

|

Improved PV characteristics |

|

Improved Co-efficient of friction |

|

Reduced water absorption |

|

Good dimensional stability |

|

FDA Compliant |

| |

|

|

|

|

| kaylon moly. |

| FEATURES: |

|

Improvement in wear property |

|

Lower co-efficient of friction |

|

Lower water asorption than kaylon

|

|

| Kaylon’s crystalisation is improved by the addition of MOS2 which increase the ultimate stress value without impairing the toughness property and also enhances the higher impact strength and sliding property is also improved. |

|

|

|

|

| kaylon H.S. |

| FEATURES: |

|

Better performance at higher operating

temp. |

|

Heat stabilized |

|

Improved mechanical properties |

|

Good dimensional stability as compared

to kaylon natural |

|

Good PV and load bearing capacity |

| |

|

|

|

|

|

|

| |