| |

| |

LDPE (LOW DENSITY POLYTHYLENE) LDPE (LOW DENSITY POLYTHYLENE)

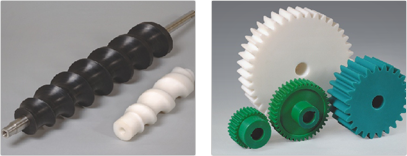

It is more flexible than HDPE which makes it a good choice for prosthetic devices

and can be vacuum formed and in thermoformed. |

| |

| |

HDPE/HMHDPE (HIGH DENSITY & HIGH MOLECULAR HIGH DENSITY POLYETHYLENE) HDPE/HMHDPE (HIGH DENSITY & HIGH MOLECULAR HIGH DENSITY POLYETHYLENE)

It is used in variety of application and industries where excellent impact even at low temperature, high tensile strength, moisture absorption, chemical and corrosion resistance properties are required. |

| |

| |

|

| Features: |

|

Good chemical and corrosion resistance |

|

|

Easy weldability & machinability |

|

|

Good thermoforming |

|

|

High Corrosion resistance |

|

|

low moisture absorption |

|

|

Good abrasion resistance |

|

|

Electrical insulating propertries |

|

|

High Strength |

|

|

High percentage elongation at break |

|

|

Usable at temp. of -50°C to + 85°C

|

|

|

No water absorption

|

|

|

|

| Application : |

|

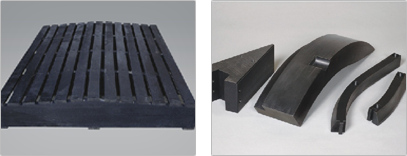

Orthopoedic and Prosthetic Devices |

|

|

light duty chain guides |

|

|

Thermoforing & material handling devices |

|

|

Water and chemical Storage tanks |

|

| |

| EXTRUDED SHEET: |

| |

| Width |

|

Length |

|

Thickness |

| 1220 |

2000 |

0.5mm to 10mm Natural & Black |

| 1000 |

2000 |

0.5mm to 15mm Natural & Black |

| 1220 |

|

10,000 |

0.5mm to 3mm Rolls |

| 1220 |

|

10,000 |

2.0mm to 5.0mm RHPGL Rolls |

| Welding Rods: 3mm dia to 5mm dia available in desired lengths. |

|

|

|

| |

| |

| Pressed Sheet: |

| |

| Width |

|

Length |

|

Thickness |

| 1230 |

2150 |

10mm to 100 mm |

| 1230 |

4330 |

10mm to 100 mm |

| Special colours are available on request . |

|

|

| |

| |

| TECHNICAL DATA |

|

|

|

|

|

|

| Property |

Test method |

Unit |

KBK HDPE

Natural |

| Density |

ISO 1183 |

g/cm3 |

0.945 |

| Molecular |

- |

Mil/mol |

>.25 |

| Tensile strength |

ISO 527-1 |

Mpa |

23 |

| Breaking strength |

ISO 527-1 |

Mpa |

36 |

| Elongation At Break |

ISO 527-1 |

% |

>300 |

| Modulus of elasticity |

ISO 527-1 |

Mpa |

800 |

| Imapact strength |

ISO 179

|

Kj/m2 |

NB |

Imapact strength 15 ° V Notch

|

ISO 179 |

Kj/m2 |

>20 |

| Ball thrust hardness 30s |

ISO 2039.1 |

N/mm2 |

40 |

| Shore Hardness D 15 s |

ISO 868 |

- |

63 |

| Wear Resistance |

Sand slurry |

- |

200-350 |

Vicat softening temp. VSP/b/50

|

ISO 306 |

°C |

67 |

| |

|

|

|

|

|

|

|

| |

| |